In today’s dynamic and complex industrial world, Distributed Control Systems (DCS) play a significant role as a vital technology in the field of industrial automation. Widely employed, DCS systems effectively control and manage intricate processes across various industries including power generation, oil and gas, water treatment, pharmaceuticals, construction, and infrastructure.

This article comprehensively examines the advantages and applications of Distributed Control Systems in various industries, their history, operation, and other important aspects of this technology. Given the diverse needs and complexities present in different industries, the importance and benefits of these systems in improving efficiency, increasing reliability, reducing costs, and enhancing flexibility are thoroughly explored.

History

Distributed Control Systems (DCS) trace back to the 1960s and 1970s. These systems were initially developed by industrial engineers to control large and complex processes such as chemical reactors and oil refineries. The early DCS systems utilized multiple controllers to perform complex control tasks. This approach, compared to traditional control systems based on a central control room and analog devices, brought significant changes and notably increased performance and accuracy.

A Distributed Control System (DCS) is a computerized control system designed to manage processes in various industries. These systems are primarily utilized in industries requiring complex and continuous process control, such as chemical, petrochemical, refineries, power plants, food processing, automotive, and more. A notable feature of DCS is the distribution of controllers throughout the system, aiding in enhancing monitoring and ensuring process performance. Without reliance on a central controller, DCS allows different process components to operate independently, thereby reducing the risk of failure in any one section.

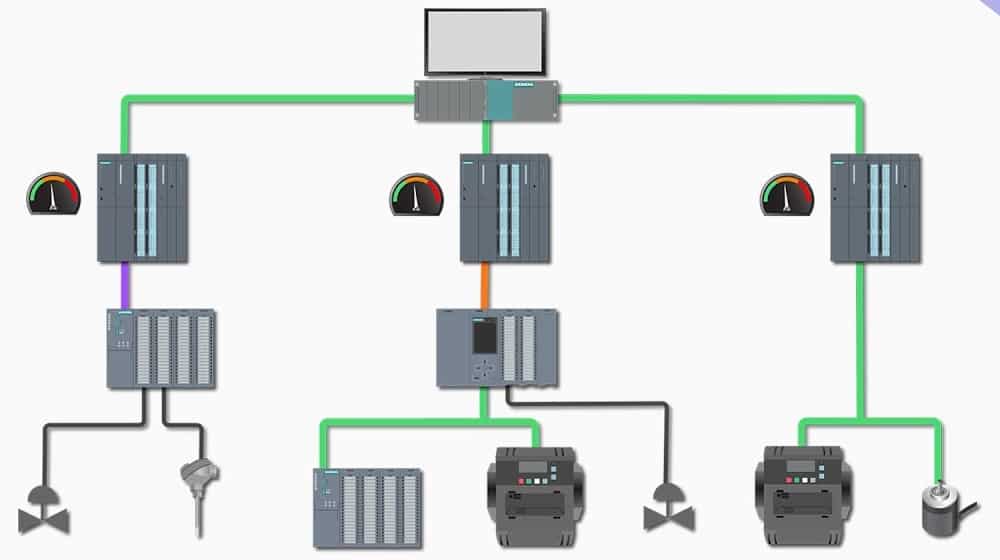

The structure of a DCS comprises several levels, including field devices, input/output modules, supervisory computers, and production control levels. This structure delineates the distribution of different control tasks and responsibilities, contributing to improved efficiency and reliability of process performance. Additionally, DCS systems leverage advanced technologies such as field signaling standards and digital protocols, facilitating their enhancement and broader applicability.

Structure and Components of a DCS Control System

The structure and components of a Distributed Control System (DCS) are designed for managing complex industrial processes by distributing control functions across multiple controllers. This hierarchical structure enhances reliability, efficiency, and flexibility in process control.

Supervisory Level

At the top level of the Distributed Control System (DCS) hierarchy, control room computers, Human-Machine Interfaces (HMIs), and engineering workstations are situated. These components collect data from processor nodes, provide a comprehensive overview of the entire process, and, if necessary, enable operator intervention.

Control Layers

Beneath the supervisory level lie the control layers, consisting of controllers, Input/Output (I/O) modules, and field devices. These layers execute control algorithms and manage process variables in real-time to ensure desired process outcomes.

Key Components

Controllers

Process controllers or local control units are the central components of a DCS. They execute control algorithms, process process variables by receiving input data from sensors and field devices, process the data, and generate output signals to manage actuators or other field devices.

Input/Output Modules (I/O)

These modules serve as the interface between controllers and field devices. Input modules receive data from field devices and convert them into a format for processing by controllers. Output modules transform signals generated by controllers into a format understandable by field devices.

Communication Networks

Communication networks connect all system components and facilitate data transmission. These networks can be wired or wireless and utilize various communication protocols such as Ethernet, Fieldbus, or industrial wireless.

Human-Machine Interfaces (HMI)

HMIs enable operators to monitor and control industrial processes. They provide graphical displays of process data, allowing operators to gain real-time insights and make informed decisions.

Engineering Station

The engineering station is the control system managing the entire DCS. It can be a computer or personal computer with specialized engineering software, enabling users to perform various engineering functions such as creating input/output nodes, configuring distributed devices, and creating new loops.

Operation of DCS Control Systems

Distributed Control Systems (DCS) operate by distributing control functions across multiple controllers throughout a process or plant instead of relying on a centralized control system. This decentralized approach increases reliability, reduces installation costs, and enables remote monitoring and control.

Main Components of a DCS

Controllers

Controllers are independent units distributed throughout the system. These units execute control algorithms and manage process variables by processing input data from sensors and field devices, and generating output signals to control actuators or other field devices.

Input/Output Modules (I/O)

I/O modules act as intermediaries between controllers and field devices. These modules receive data from field devices, convert them into a format for processing by controllers, and vice versa, change output signals into a format understandable by field devices.

Communication Networks

Communication networks connect all system components and facilitate data transmission. These networks ensure reliable and real-time data transmission while minimizing delays and data loss.

Supervisory Computers

Supervisory computers gather information from processor nodes in the system and provide operator control screens. These computers enable operators to remotely monitor and control processes.

Operation of a DCS

The operation of a Distributed Control System (DCS) involves multiple levels of control and supervision:

Level 0

This level includes field devices such as flow and temperature sensors, as well as final control elements like control valves.

Level 1

In this level, industrial I/O modules and distributed electronic processors are located.

Level 2

This level comprises supervisory computers that collect information from processor nodes and provide operator control screens.

Level 3

The focus of this level is on production control, production monitoring, and goal monitoring.

Level 4

This level is dedicated to production planning.

Role and Application of DCS

DCS systems are designed for data collection, process regulation, real-time monitoring, and safety assurance. They utilize specialized algorithms and logical routines for real-time data analysis and decision-making. For instance, regulating valve positions, motor speeds, or initiating specific process stages are among DCS tasks. These decisions rely on predefined control strategies and live data inputs, ensuring that industrial processes operate within desired parameters and enhance efficiency and product quality.

Widespread Applications of DCS

DCS systems have a wide range of applications across various sectors, including oil and gas operations, power generation facilities, chemical and pharmaceutical plants, water and wastewater treatment, and food and beverage operations. Their capability to control extensive or entire plant processes has made them an essential tool in modern industrial automation.

Application of Control Systems (DCS)

Distributed Control Systems (DCS) serve as vital tools for controlling and automating complex processes in various industries. These systems are used in different industrial domains, including power generation, oil and gas, water treatment, pharmaceuticals, biotechnology, manufacturing, and industrial infrastructure. Below are some key applications of these systems:

Power Generation

In coal-fired, gas-fired, and nuclear power plants, DCS is used to control and monitor power generation processes. These systems manage process variables such as temperature, pressure, flow, and level to ensure the safe and efficient operation of these processes.

Oil and Gas

DCS is employed in drilling, refining, and petrochemical production processes in the oil and gas industry. These systems control variables such as pressure, flow, and level, ensuring the safe and efficient performance of these processes.

Water Treatment

DCS is used in water treatment, desalination, and wastewater treatment processes. These systems manage process variables such as flow rate, pH, and temperature to ensure the safe and efficient operation of these processes.

Pharmaceuticals and Biotechnology

DCS is utilized in fermentation, distillation, and purification processes in the pharmaceutical and biotechnology industries. These systems control variables such as temperature, pH, and pressure, ensuring the safe and efficient performance of these processes.

Manufacturing

In the manufacturing industry, DCS is employed to control assembly lines, robotic systems, and packaging systems. These systems manage process variables such as temperature, pressure, flow rate, and level to ensure the safe and efficient operation of these processes.

Infrastructure

DCS is used in the infrastructure of traffic control systems, building automation systems, and transportation systems. These systems manage process variables such as temperature, pressure, flow rate, and level to ensure the safe and efficient operation of these processes.

Read more: Phase Control

Advantages of DCS Control Systems

The use of Distributed Control Systems (DCS) in various industries offers significant advantages for the following reasons:

Increased Efficiency

DCS systems improve process efficiency by assigning independent controllers to each section of the process. These controllers can operate simultaneously and in parallel with each other, making rapid and effective decisions.

Enhanced Reliability

The distributed architecture of DCS increases system reliability. In the event of a failure in one part of the system, other parts continue to operate, reducing downtime and increasing process stability.

Increased Flexibility

Thanks to their distributed architecture, DCS systems are easily customizable, allowing industries to update the system with changes in processes and requirements.

Reduced Installation and Operation Costs

In comparison to centralized control systems, DCS systems typically have lower installation and operation costs. This is due to the use of fewer central controllers and reliance on network-based systems.

Remote Monitoring and Control Capability

With the presence of advanced communication networks, DCS systems enable operators to easily monitor and control processes remotely, contributing to improved efficiency and safety of the processes.

Adaptability to Industry Needs

DCS systems, due to their extensive configuration and settings, can adapt to the specific needs of each industry and process, providing optimal performance.

Summary

As a result, Distributed Control Systems (DCS) serve as a vital tool in industrial automation, used in various industries such as power generation, oil and gas, water treatment, pharmaceuticals, manufacturing, and infrastructure. These systems offer significant benefits such as increased efficiency, enhanced reliability, reduced operational costs, and improved flexibility. With the growing importance and advancements in various industries, the optimal deployment and flexibility of distributed control systems can greatly contribute to achieving industrial and economic objectives.

Read more: Buy LS contactor from Iran