In the field of industrial electrical engineering, voltmeters are considered one of the most essential and crucial tools. These instruments are used to measure electrical voltage in devices and electrical circuits, playing a vital role in conducting experiments, repairs, and electronic projects. With the advancement of technology, voltmeters are designed and manufactured in various forms and types, ranging from analog to digital, each with its unique features and applications. This article will delve into the history, types, and applications of voltmeters, and examine the top brands of this tool.

History of the Voltmeter

Voltmeters, being one of the essential tools in electrical and electronic science, have a history closely intertwined with that of multimeters.

Early Development:

The concept of measuring voltage or electrical potential difference dates back to the nineteenth century with the invention of the galvanometer by Hans Christian Ørsted in 1820. The galvanometer, initially designed to detect electrical current, was the first instrument capable of indicating electrical voltage.

The First Multimeter

In 1920, Donald Macadie, an engineer at the British Post Office, invented the first multimeter. Known as the AVOmeter, this tool could measure not only voltage but also current and resistance, and it could handle both AC and DC measurements. The AVOmeter quickly became an essential tool for communication line work.

Evolution of the Multimeter

During the 1930s, multimeter technology saw significant advancements. The introduction of the copper oxide rectifier by Westinghouse allowed multimeters to measure both AC and DC currents simultaneously. These tools improved not only in measurement capabilities but also in accuracy and speed.

Digital Voltmeter

In the 1950s, with the advancement of electronics and semiconductors, multimeters evolved into digital devices. This shift from analog to digital displays brought higher accuracy and speed to measurements.

Modern Multimeters

From the 1950s to the present, multimeters have continued to evolve, offering a wide variety of features and capabilities. These tools are now indispensable for many technicians, engineers, and trainees in the electrical and electronics fields, used extensively for various electrical measurements and tests.

Definition and Operation of a Voltmeter

A voltmeter is a specialized electrical instrument used to measure the electrical potential difference or voltage between two points in an electrical circuit. This tool is typically calibrated to provide voltage readings in units such as volts (V) and millivolts (mV), making it essential for evaluating the health and performance of electrical systems.

The operation of a voltmeter is based on Ohm’s Law, which states that voltage (V) is equal to the product of current (I) and resistance (R): V = IR. The voltmeter is connected in parallel with the part of the circuit where the voltage measurement is desired. Due to its high input impedance, it draws a negligible amount of current from the circuit, ensuring minimal disturbance. The voltmeter then displays the voltage based on the current passing through it and its internal resistance.

Components and Operation of Voltmeters

Voltmeters consist of several components, including a voltage sensing element (typically a coil or resistor), a display mechanism (either analog or digital), and circuitry to convert the measured voltage into a readable format. Input terminals allow connection to the measurement circuit, while protective casings ensure safety and durability.

Analog Voltmeters

Analog voltmeters use a moving needle or pointer on a scale to indicate voltage values. These instruments typically consist of a galvanometer and a series resistor. The galvanometer responds to the magnetic field generated by the current passing through the circuit, moving the needle based on the measured voltage.

– Construction and Operation: Analog voltmeters are composed of a galvanometer and a series resistor. The galvanometer is sensitive to the magnetic field produced by the current flowing through the circuit, causing the pointer to move across a scale in proportion to the voltage measured.

– Applications: Analog voltmeters are commonly used for measuring both AC and DC voltages and are sensitive to voltages above 100 volts. They can be designed to measure a wide range of voltages, from fractions of a volt to several thousand volts.

– Advantages: Analog voltmeters are relatively simple and inexpensive, making them suitable for applications where a visual representation of voltage is needed.

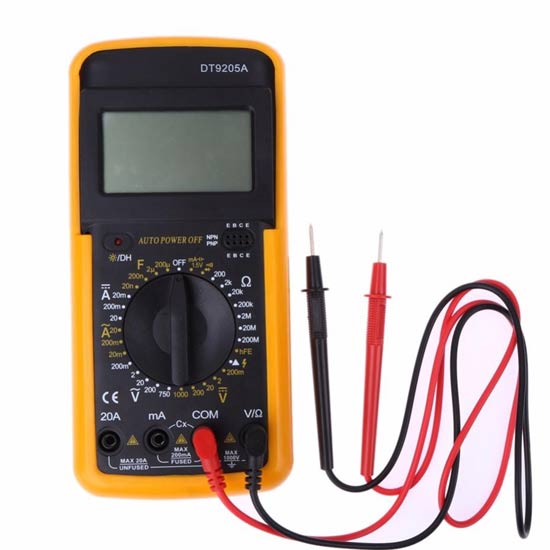

Digital Voltmeters

Digital voltmeters display voltage readings in a numerical digital format, providing higher accuracy and ease of use. These instruments utilize an analog-to-digital converter to present a digital readout of the voltage.

– Construction and Operation: Digital voltmeters use an analog-to-digital converter to transform the measured voltage into a numerical value displayed on a digital screen. This design enhances accuracy and simplifies reading the voltage.

– Applications: Digital voltmeters are widely used in various fields for precise voltage measurement and are preferred for their ease of use and accuracy.

– Advantages: Digital voltmeters offer higher precision, easier readability, and typically include additional features such as data logging and automatic range selection.

Types of Voltmeters

Voltmeters can be categorized into two main types: analog and digital.

1. Analog Voltmeters:

– Construction and Operation: Consist of a galvanometer and a series resistor. The galvanometer detects the magnetic field generated by the current and moves the pointer accordingly.

– Applications: Used for measuring AC and DC voltages, especially suitable for voltages above 100 volts. They can measure a wide range of voltages from fractional volts to several thousand volts.

– Advantages: Simple, cost-effective, and provide a visual display of voltage.

2. Digital Voltmeters:

– Construction and Operation: Utilize an analog-to-digital converter to display voltage readings in a digital format.

– Applications: Preferred for precise voltage measurements in various fields due to their accuracy and ease of use.

– Advantages: Offer higher precision, easy readability, and additional features like data logging and automatic range selection.

Digital Voltmeters

Construction and Operation

Digital voltmeters (DVMs) utilize an analog-to-digital converter (ADC) to transform the analog signal from the circuit into a digital value that is displayed numerically. This conversion process allows for highly accurate and precise voltage measurements.

Read more: Buy Hyundai Contactor From Iran

Types of DVMs

Digital voltmeters can operate using either ramp or successive approximation methods. The ramp method measures the time it takes for the voltage signal to reach a specific level. In contrast, the successive approximation method employs a digital-to-analog converter (DAC) and successive approximation register (SAR) to convert the analog voltage signal into a digital value.

Applications

Digital voltmeters are widely used across various fields for measuring voltage levels in circuits. They are essential in applications requiring high accuracy and precision, such as laboratories, industrial settings, and electronic work.

Advantages

Digital voltmeters offer several benefits:

– High Accuracy: They can measure voltages with great precision.

– Elimination of Human Error: The digital readout minimizes human error.

– Stability: They are not affected by external conditions such as temperature.

– Versatility: Digital voltmeters are versatile, can operate with minimal power, and provide readings without manual intervention.

Comparison of Analog and Digital Voltmeters

Both digital and analog voltmeters are essential tools, but they differ in features and accuracy. Generally, a digital voltmeter (DVM) is more accurate than an analog voltmeter. Digital voltmeters typically offer accuracy better than one percent, with some models achieving accuracy of a few parts per million. This high level of precision is due to the use of an analog-to-digital converter (ADC) to transform the voltage signal into a digital value.

In contrast, analog voltmeters may have an accuracy of around a few percent of the full scale. The accuracy of an analog voltmeter depends on its specific design and the quality of its components.

Analog voltmeters are less sensitive to environmental conditions like temperature and can operate without an external power source. Digital voltmeters, however, require an external power supply. Additionally, due to their simpler construction and minimal electrical noise interference, analog voltmeters can be the best choice in certain situations.

Applications of Voltmeters

Voltmeters, as instruments for measuring voltage in electrical and electronic circuits, play a crucial role in various industries and applications. These devices enable users to measure different voltage levels and assess the performance of circuits, devices, and equipment. The primary applications of voltmeters include:

– Industrial and Manufacturing: In industrial settings, voltmeters are used to monitor voltage levels in machinery, industrial electrical supplies, and production lines. They help ensure the proper and stable operation of these systems and identify potential issues in a timely manner.

– Automotive Industry: In the manufacturing and maintenance of vehicles, voltmeters are used to check the voltage of batteries, ignition systems, alternators, and other electrical components. This application helps diagnose problems and faults in vehicle electrical systems.

– Scientific Research: In laboratories and research centers, voltmeters are used to measure voltage in experimental equipment and electrical circuits. These tools are invaluable for calibrating equipment and analyzing experimental data.

– Home Applications: Homeowners and DIY enthusiasts can use voltmeters to check voltage levels in their home electrical systems. These instruments help identify potential issues such as voltage drops or power surges.

– Energy Management: In energy management systems, voltmeters monitor voltage levels in power grids and related equipment. They ensure the stability and reliability of power supplies and help identify issues that can affect power quality.

Overall, voltmeters are essential tools in various industries and applications, providing accurate voltage measurements and contributing to the safe and efficient operation of electrical systems.

Read more: Review of Various Best Practices in Testing Electrical Panels