Power Factor Correction (PFC) is a fundamental issue in the field of industrial electrical engineering and electronics that significantly impacts the efficiency and performance of electrical systems. In today’s world, where the use of electronic and electrical devices is on the rise, the importance of optimizing energy consumption and enhancing the efficiency of power grid connections is more critical than ever. The power factor is the ratio of real power to apparent power and typically ranges from 0 to 1. As the power factor approaches 1, the efficiency of the system improves, preventing increased energy consumption.

In this article, we introduce and examine various methods of power factor correction. First, we will explore passive PFC methods, which involve using capacitors and inductors to compensate for phase delay caused by inductive loads. Then, we will delve into active PFC methods, which improve the power factor by controlling the input current using electronic components and control systems.

Given that power factor correction has a direct impact on the efficiency and productivity of electrical systems, understanding these methods is crucial for engineers and professionals in the field of electrical and electronics engineering. In the following sections of this article, we will analyze the advantages and disadvantages of each method, compare them, and provide recommendations for their appropriate use.

Types of Power Factor Correction Methods

In Power Factor Correction (PFC), there are generally two main methods used to improve the efficiency of power supplies and ensure compliance with electrical standards: passive and active methods. Each of these methods has its own specific advantages and disadvantages and can be selected for different applications based on specific needs.

Passive

Power Factor Correction (PFC) Using Passive Methods

Passive power factor correction is a common method for improving the performance of power supplies. This method uses simpler electronic components compared to active methods and is typically suitable for applications with lower power requirements.

Types of Passive PFC Methods:

Capacitor Input Filter: This method, also known as the pi filter, uses capacitors to correct the power factor. The capacitors in the filter continuously charge and discharge, storing and delivering instantaneous energy. This action removes unwanted frequencies from the signal and optimally reduces harmonics, thereby improving the performance of the power supply. Due to its simplicity and reliability, this method is often the first choice for certain applications. Examples of applications using this method include small to medium power supplies that require power factor correction.

In summary, passive PFC methods offer a straightforward and cost-effective solution for improving power factor in lower-power applications, making them a popular choice for many common power supply needs.

Valley-Fill PFC:

The Valley-fill PFC method uses capacitors and diodes to charge and discharge capacitors in parallel around the valley point. In this method, the capacitors are continuously charged and discharged, resulting in a ripple voltage that effectively produces a DC output. This method is particularly suitable for applications that require ripple voltage. Generally, in this method, capacitors are connected in series around the ripple valley point, and diodes ensure their discharge at appropriate moments.

Advantages:

Cost-effective and Efficient: Passive PFC methods are usually less expensive compared to active methods, and their simplicity translates to lower implementation costs.

Simplicity and Reliability: Using simpler electronic components in this method increases reliability and reduces technical risks.

Minimal EMI Production: This method generates fewer electromagnetic waves, which can be a significant advantage in certain applications.

Disadvantages:

Size and Weight: Due to the use of large inductors, the components in this method can be bulky and heavy, which can be problematic in some applications.

Power Limitations: Passive PFC methods are generally suitable for smaller power supplies and do not perform optimally in high-power applications.

In summary, the Valley-fill PFC method offers a cost-effective and reliable solution for applications with lower power requirements and where minimal electromagnetic interference is desirable. However, it may not be suitable for high-power applications due to its size, weight, and performance limitations.

Active Power Factor Correction (PFC) Method

The active power factor correction (PFC) method is a more advanced approach compared to passive methods, utilizing active electronic components such as MOSFETs, BJTs, and IGBTs to enhance the performance of power supplies. This method is particularly suitable for high-power supplies, especially those exceeding 100 watts, and can significantly improve the efficiency and accuracy of power factor correction. Here, we introduce the active PFC method, its applications, advantages, and disadvantages:

Active PFC Method

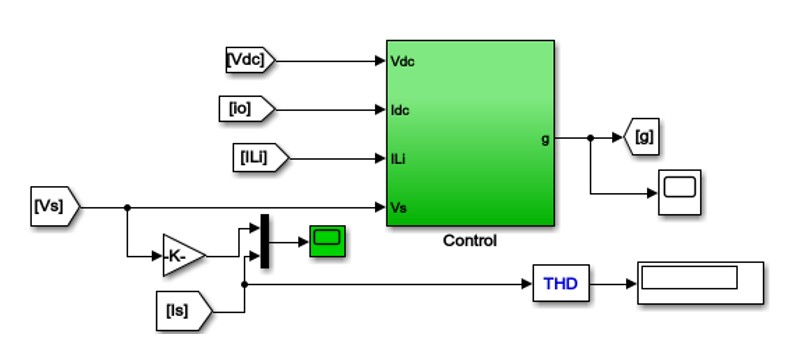

The active PFC method employs active electronic components to convert the input AC voltage into a high-quality, direct DC voltage. This method often utilizes boost converters, which provide a higher DC output voltage than the input DC voltage.

Applications: The active PFC method is particularly useful for high-power supplies and applications that require more precise power factor correction. This includes industrial power supplies, various electronic devices, medical equipment, and solar energy systems.

Advantages:

Improved Efficiency: The active PFC method can achieve a power factor of over 0.95, which increases the efficiency and usability of power supplies.

Precise Voltage and Current Control: This method allows for precise control of voltage and current, leading to better and more stable power supply performance.

Reduced Voltage Fluctuations: By using the active PFC method, AC input voltage fluctuations are significantly reduced, resulting in longer lifespan and better performance of power supplies.

Disadvantages:

Complexity and Cost: The active PFC method incurs higher costs due to the use of more complex electronic components, and it requires more intricate design and construction.

Side Effects: The use of sophisticated electronics and control systems in the active PFC method can lead to side effects such as electromagnetic interference (EMI), necessitating careful prediction and control.

Comparison of Methods

Comparing active and passive methods in power factor correction (PFC) to achieve power factor integrity and compliance with industrial standards can be assessed based on several aspects. Below is a brief comparison of these two methods, considering their advantages and disadvantages:

Efficiency:

Active PFC is generally more efficient, capable of achieving high power factors close to 1 under varying load conditions, whereas passive PFC may offer lower efficiency.

Complexity and Cost:

Active PFC involves more complex circuits and control systems, resulting in higher costs. Due to this complexity, its implementation is more expensive.

Passive PFC uses simpler components and a low-cost control system, making it less expensive.

Adjustability:

Active PFC is highly adjustable and suitable for a wide range of loads and operating conditions.

Passive PFC has limited adjustability and fewer settings available.

Control System:

Active PFC requires more sophisticated control systems that may need more complex configurations and adjustments.

Passive PFC operates with simpler control systems, often fixed or timer-based.

Power Factor Range:

Active PFC can achieve high power factors close to 1 under various load conditions.

Passive PFC may have a limited correction range and performance under different loads.

Summary

Active Power Factor Correction (PFC) Method:

Active PFC is an advanced approach that uses active electronic components such as MOSFETs, BJTs, and IGBTs to enhance power supply performance. It is suitable for high-power supplies, particularly those exceeding 100 watts, and significantly improves efficiency and accuracy. Active PFC converts input AC voltage into a high-quality, direct DC voltage using boost converters, providing higher DC output voltage than the input.

Applications:

Industrial power supplies, electronic devices, medical equipment, and solar energy systems benefit from active PFC due to its high efficiency and precise power factor correction.

Advantages:

– Achieves power factors over 0.95, increasing efficiency.

– Provides precise control of voltage and current, ensuring stable performance.

– Reduces AC input voltage fluctuations, enhancing power supply lifespan.

Disadvantages:

– Higher costs and complexity due to advanced electronic components.

– Potential electromagnetic interference (EMI) requiring careful control.

Comparison of Active and Passive PFC Methods:

Efficiency: Active PFC is more efficient, achieving power factors close to 1, while passive PFC may offer lower efficiency.

Complexity and Cost: Active PFC is more expensive due to complex circuits and control systems; passive PFC is less costly with simpler components.

Adjustability: Active PFC is highly adjustable, suitable for various loads and conditions; passive PFC has limited adjustability.

Control System: Active PFC requires sophisticated control systems; passive PFC uses simpler, often fixed or timer-based systems.

Power Factor Range: Active PFC achieves high power factors under varying loads; passive PFC has a limited correction range.

Read more: Review of Various Best Practices in Testing Electrical Panels

Adherence to Standards:

Active PFC is often necessary to comply with international standards for power factor correction.

Passive PFC may be suitable for applications with lower power factor requirements but less precise.

In summary, the choice between these two methods depends on needs, application environments, and considerations of cost and complexity. When high efficiency and compliance with international standards are of paramount importance, active PFC may be the better choice, whereas in cases where circuit cost and complexity are more critical, passive PFC may be the preferable option.

Some common applications where passive PFC is preferred over active PFC include:

High-End Electronics Applications:

In high-end electronics applications, especially in industries like large televisions, computer monitors, and audio devices, passive PFC is often preferred. This is due to its ability to tolerate high effective ripple voltage in DC output, which is undesirable for dynamic and unstable load applications.

Low-Power Applications:

In devices with low energy consumption and no precise need for high efficiency and power factor correction, such as LED lamps and low-power household appliances, passive PFC is usually the best option. Its simplicity and low cost make it a suitable choice for these applications.

Applications with Stable Loads:

In applications where the load is relatively stable and undergoes little significant change over time, passive PFC is preferred. Because passive methods are generally less sensitive to load changes, they are more reliable for these applications.

Applications with Simple Requirements:

For applications that do not require high power factor correction or where power factor is not a critical factor, passive PFC provides a simple and cost-effective solution. The simplicity of passive PFC circuits makes their implementation and maintenance easy.

Applications with Size and Weight Constraints:

In some applications with limited space, such as portable medical devices and communication equipment, passive PFC is preferred due to its fewer and lighter components used.

Therefore, passive PFC is favored in applications that require simplicity, reliability, and cost-effectiveness, especially in low-consumption and stable load scenarios.

Some common applications where active PFC is preferred over passive PFC include:

High-Power Applications:

In devices and equipment with high energy consumption, such as industrial equipment, communication systems, and energy-intensive equipment, active PFC is preferred. This method can achieve higher power factors and improve energy efficiency.

Applications Requiring High Efficiency:

In applications where energy efficiency is of paramount importance, such as HVAC systems, advanced medical devices, and computer systems, active PFC is preferred. This method can help reduce harmonics and improve energy efficiency.

Applications with Dynamic Loads:

In applications where the load may change significantly over time, such as industrial systems with variable loads, high-power computer systems, and advanced communication equipment, active PFC is preferred. This method can dynamically regulate the input current and provide optimal performance while maintaining a high power factor.

Applications Requiring Compliance with Standards:

In applications where adhering to international standards for power factor correction is essential, such as large industries, power plants, and electrical network equipment, active PFC is preferred. This method can achieve higher power factors and easily synchronize with relevant standards.

Applications with Size and Weight Constraints:

In applications where the size and weight of components are crucial, such as portable medical devices, mobile communication devices, and military equipment, active PFC is favored. This approach can allow necessary changes in the size and weight of the device by using more compact and lightweight circuits.

Therefore, active PFC is preferred in applications requiring high power factor correction, efficiency, and compliance with international standards. Additionally, it is suitable for applications with dynamic loads and places where space and weight are not critical limitations.

Summary:

In this article, two power factor correction methods, namely active PFC and passive PFC, have been examined.

Active PFC utilizes advanced electronic components and control systems to regulate the input current dynamically, while passive PFC relies on simpler designs. In applications requiring compliance with standards, high efficiency, or energy efficiency, active PFC is preferred. On the other hand, passive PFC is suitable for applications with stable loads, size and weight constraints, or situations where circuit cost and complexity are not significant. The appropriate choice between these two methods should be made based on the specific needs and limitations of each application. This review demonstrates that each of these methods has its own characteristics, advantages, and disadvantages that should be considered when selecting them.

Read more: Review of Various Pneumatic Key Accessories and Their Applications