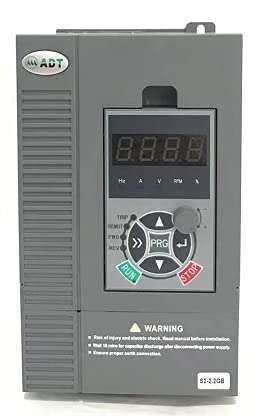

Perhaps you have wondered why you should purchase and utilize the ADT inverter. In the following, we will provide an answer to this question and assist you in experiencing the best choice.

About ADT

ADT, an abbreviation for Advanced Drive Technology, refers to drives with advanced technology and is manufactured in South Korea.

This inverter is produced in South Korea, with its factory located in the city of Seoul. The ADT inverter, specifically the U1 model or imaster U1, is currently available in four models in Iran. The ADT inverter model U1 is produced in both single-phase and three-phase models.

This inverter is a powerful device equipped with all the necessary specifications for the operation of various industrial machinery.

The imaster U1 inverter is designed similarly to the Fuji inverter from Japan and is highly similar to the Fuji drive in terms of both software and hardware.

Furthermore, this inverter has compact dimensions and is small in size, making it highly significant in the context of assembly or replacement for damaged drives.

Features of the U1 Model

The ADT U1 model inverter is equipped with a volume control on the keypad, and additionally, it supports the connection of an external keypad.

This type of inverter is designed and manufactured in both single-phase and three-phase variants, ranging from 0.4 kW to 2.2 kW for single-phase and 0.4 kW to 4 kW for three-phase.

The U1 model inverter in all power capacities comes with an internal braking unit. The imaster U1 inverter features both V/F control mode and Sensorless vector control mode.

The U1 series inverter has the capability of Auto Tuning, allowing for automatic measurement of motor parameters. It can also inject torque up to 150% of the rated torque at a frequency of 1 Hz. The U1 model inverter includes analog voltage and current input terminals.

The imaster U1 inverter is equipped with two digital input terminals for motor rotation direction (clockwise and counterclockwise) and three digital input terminals (X1, X2, and X3) programmable for up to 16 different speeds. The U1 model inverter offers two types of outputs: relay and transistor.

The U1 series inverter allows manual and automatic torque adjustment. The imaster U1 inverter can generate output frequencies ranging from 0.1 Hz to 400 Hz.

The ADT imaster U1 inverter encompasses a frequency range from 1 Hz to 15 kHz and features an input voltage variation range from 15% to +10%. One of the capabilities of the imaster U1 model is the option to select the input signal as NPN or PNP.

The U1 model inverter includes an advanced PID controller and a built-in RS485 communication port. It complies with UL, CE, and ROHS standards and boasts a lifespan exceeding 40,000 hours due to its special structure.

Equipped with a cooling fan and heat sink, the imaster U1 inverter utilizes IGBTs from Mitsubishi, Japan. This model offers high power and torque, an aesthetically pleasing appearance, compact dimensions, robust software and hardware, and an 18-month warranty.

The imaster U1 inverter is competitively priced and is currently one of the best-selling high-quality Asian inverters in the Iranian market. It is suitable for a wide range of light and heavy industrial applications and has been utilized in various industries to date.

The U1 model inverter is well-suited for applications such as conveyor belts, fan systems, extruders, mixers, mills, elevators, tension control systems, textile industries, industrial coolers, and most common projects. The imaster U1 drive comes with a user-friendly installation guide and a catalog in Persian for easy setup and operation.

ADT A1 Series Inverter

The imaster A1 model inverter is considered a heavy-duty workhorse. This inverter is produced in two voltage types: three-phase with a voltage range of 200 to 230 volts and a power range of 5.5 kW to 90 kW, and three-phase with a voltage range of 380 to 480 volts and a power range of 5.5 kW to 132 kW. Currently, the power range available in the Iranian market is from 5.5 kW to 132 kW with a voltage of 380 to 480 volts.

Features of the ADT A1 Model Inverter

The imaster A1 model inverter offers V/F control modes, sensorless vector control, and close-loop control. It comes with two keypad models: LED and LCD. The keypads are detachable, allowing installation at a distance from the inverter using a communication cable.

The imaster A1 inverter has analog voltage and current inputs and an internal PID controller. It includes an Auto Tuning parameter, allowing automatic measurement of motor parameters in static conditions.

The ADT imaster A1 series inverter can inject a frequency output ranging from 0.1 Hz to 400 Hz to the motor, with a carrier frequency range between 1 Hz and 15 kHz.

In the A1 series inverter, the input voltage variation range is between 15% and +10%. The input signal can be selected as NPN or PNP. The imaster A1 series inverter has the capability to control a second motor along with adjusting the relevant parameters. It features a Built-in RS485 communication port.

ADT imaster A1 Drive

The imaster A1 model drive from ADT features an internal brake unit for powers up to 22 kW, allowing direct connection of the brake resistor to the inverter. The A1 series drive is equipped with an EMC filter and an internal DC reactor. Adding electronic input and output boards is possible as an optional feature.

The ADT imaster A1 drive offers communication protocol options, including Profibus-DP, DeviceNET, ModbusTCP, and Encoder protocols.

The imaster A1 series inverter complies with RoHS and CE standards. Due to its high power and torque capabilities, the imaster A1 drive is suitable for a wide range of industrial applications, including windmills, tower cranes, hoists, extruders, crushers, mills, textile machinery, traction rollers, and more. The imaster A1 inverter is dual-rated, meaning a 90 kW A1 model drive can be utilized as a heavy-duty 90 kW or a light-duty 110 kW system.

The A1 series drive features a professional cooling system equipped with fans and cooling heat sinks. The substantial dimensions of this ADT inverter allow for rapid heat transfer and dissipation.

In sensorless vector control mode, the imaster A1 inverter can inject up to 200% of the rated torque to the motor at a frequency of 1 Hz. The A1 series drive incorporates all necessary protective modules, ensuring adequate protection against factors that could harm the motor or the inverter.

The A1 series ADT inverter includes a DC reactor ranging from 30 kW to 132 kW in power.

ADT E1 Series Inverter

The ADT imaster E1 series inverter is manufactured in three voltage types. The first type includes single-phase inverters with a voltage range of 200 to 230 volts and a power range of 0.4 kW to 2.2 kW. The second type comprises three-phase inverters with a voltage range of 200 to 230 volts and a power range of 0.4 kW to 22 kW. The third type, currently available in Iran, consists of three-phase inverters with a voltage range of 380 to 480 volts and a power range of 0.4 kW to 350 kW.

The imaster E1 series inverter is designed for heavy-duty applications and is used across various industries with V/F control and Sensorless vector control.

Features of the E1 Model

The imaster E1 inverter features a detachable keypad, allowing for communication over a longer distance using a communication cable. The ADT E1 model inverter includes analog voltage and current inputs and an advanced PID controller. The imaster E1 drive has the capability to measure all motor parameters in static conditions.

The ADT imaster E1 inverter can generate an output frequency ranging from 0.1 Hz to 400 Hz, and the carrier frequency range in the E1 inverter spans from 1 Hz to 15 kHz.

ADT E1 Series Inverter

The imaster E1 model drive offers a voltage input variation range from 15% to +10% and the capability to select the input control signal as either NPN or PNP. The ADT E1 series inverter has the ability to control a second motor. The imaster E1 drive is equipped with a Built-in RS485 communication port.

The E1 series inverter from ADT, up to a power of 22 kW, comes with an internal braking unit, enabling the direct connection of a braking resistor to the E1 drive. The imaster E1 drive adheres to UL, CE, and RoHs standards. Designed based on the specifications of Hyundai’s N700E series drive, the imaster E1 model drive distinguishes itself with enhanced software capabilities.

The ADT E1 series inverter features a Built-in EMC filter and DC reactor. The imaster E1 drive, as an option, supports communication protocols such as Profibus_DP, Device-net, ModbusTCP, and Encoder.

Overall, the ADT imaster E1 series inverter boasts an appealing design, competitive pricing, an extended lifespan, an 18-month warranty, and robust performance. It is suitable for a wide range of industrial applications.

The E1 model inverter is dual-rated, exemplified by the E1 drive with a power of 280 kW, where it can operate as a heavy-duty 280 kW High Overload (HF) or a light-duty 320 kW Heavy Fan and Pump (HFP).

The ADT E1 series inverter finds applications in various industrial settings, including cranes, windmills, tower cranes, extruders, conveyor belts, fans and pumps, mills, mixers, textile industries, petrochemical industries, and more.

The imaster E1 inverter from ADT comes with a user manual and a catalog in Persian, making it easy for electrical colleagues and project executors to install and operate.

ADT C1 Series Inverter

The ADT imaster C1 series inverter is produced in two types. The first type is three-phase with a voltage range of 200 to 230 volts and a power range of 0.4 kW to 22 kW. The second type is three-phase with a voltage range of 380 to 480 volts and a power range of 0.4 kW to 22 kW. Currently, the three-phase 380 to 480 volts model is available in the Iranian market.

The imaster C1 series inverter from ADT has the capability to inject high torque at low frequencies. The C1 drive features two control modes: V/F control and Sensorless vector control.

Features of the C1 Model:

The ADT imaster C1 series inverter is equipped with a detachable keypad, facilitating remote operation through a communication cable. The C1 drive has analog voltage and current inputs and an advanced PID controller.

The imaster C1 series inverter has an optional Built-in EMC filter. This drive also has the ability to execute KEB functions. The C1 model drive incorporates an algorithm for optimizing motor losses, allowing for energy savings.

The C1 drive includes external brake control for elevators and lifts. The imaster C1 series inverter can be installed in parallel without spacing. The C1 model inverter has an output frequency range between 0.1 Hz and 400 Hz, and the carrier frequency can vary between 1 and 16 kHz.

ADT imaster C1 Inverter Features

The imaster C1 series inverter is equipped with an internal chopper, allowing for the direct connection of a braking resistor. This feature enhances the control and braking capabilities of the C1 drive.

The ADT inverter offers optional communication protocols, including Ethernet/IP, Profinet/IO, and DeviceNET. The imaster C1 drive complies with RoHS, CE, and UL standards. It features a cooling fan and heat sink, presenting an aesthetically pleasing design with excellent performance. With high power and robust software capabilities, the ADT C1 series inverter is suitable for heavy-duty, light-duty, and semi-heavy-duty industrial applications, supporting power capacities up to 22 kW.

The imaster C1 inverter comes with a comprehensive guidebook and a catalog in Persian. Electrical professionals and project managers can utilize these resources for the installation and commissioning of the inverter.

In this article, we have provided a detailed explanation of the ADT inverter. For the procurement of these inverters, it is recommended to contact electro-mechanical experts who can guide you through the selection and implementation process.