In this article, we aim to explain what a breaker is and the differences it has compared to a disconnect switch and a sectionalizer. Stay with us as we delve into understanding the distinctions between these equipment types once and for all.

You might be familiar with terms like sectionalizer, disconnect switch, breaker, and similar ones, but at times, you may not have fully grasped the meanings of these terms.

Continuing on, we will introduce these pieces of equipment and then examine various types of disconnect switches.

What is a Sectionalizer?

Similar to a disconnect switch, a sectionalizer is a circuit interrupter, but with the difference that it cannot be used as a circuit breaker under load. It is not possible to use a sectionalizer as a circuit breaker under load. When a sectionalizer is in the circuit and we want to disconnect it, the main power must have been previously cut off by a disconnect switch.

However, in situations where low-power consumers are present, a sectionalizer can be used for circuit interruption and reconnection. In conditions where the load is not very heavy, a disconnect switch is not utilized.

For example, on top of 20-kilovolt step-down transformers to 400 volts found in the streets, a sectionalizer is installed to cut off the 20-kilovolt power using the same sectionalizer.

Utilization of Sectionalizers in the Input and Output of Disconnect Switches

During the maintenance and repair of disconnect switches, sectionalizers are employed. The sectionalizer safely de-energizes the circuit during repairs and other activities, providing assurance of a de-energized network by inspecting its well-visible contacts. Sectionalizers are designed to be disconnectable under load.

In most cases, the installation of a power switch with rapid disconnect and reconnect capabilities is not essential. Additionally, in smaller networks and substations, installing a power switch, sectionalizer, and related components incurs high costs on the system. Therefore, in such scenarios, sectionalizers that are disconnectable under load or load-break switches are used. These switches, in addition to performing the tasks of a sectionalizer, serve the function of interrupting the current in the network as a low-power switch. Thus, in these sectionalizers, a device is integrated to achieve an immediate current interruption.

The connecting power of these sectionalizers is significantly high and capable of connecting currents ranging from 25 to 75 kiloamperes (maximum effective current). However, their disconnecting power is much lower than their connecting power and is around their rated current (which falls between 400 to 1500 amperes). Considering these capabilities, it can be inferred that these switches are not used for interrupting short-circuit currents. In the case of deployment in high-voltage networks, it is necessary for the disconnecting power of the switch to exceed its short-circuit connecting power, or the switch should be equipped separately as a short-circuit current interrupter.

Classification of Ground Disconnect Switches or Sectionalizers

Sectionalizers are categorized based on various features such as the type of insulating material, construction, operating mechanism, and installation location.

1. Based on the type of insulating material:

– Sectionalizers with air insulation

– Sectionalizers with SF6 insulation

2. Based on construction:

– Horizontal sectionalizers with single-point disconnect

– Horizontal sectionalizers with double-point disconnect

– Vertical sectionalizers

3. Based on the type of operating mechanism:

– Sectionalizers with motorized mechanism

– Sectionalizers with manual mechanism

– Sectionalizers with a combination of manual and motorized mechanisms

4. Based on the installation location:

– Sectionalizers installed in an outdoor environment (external class)

– Sectionalizers installed in an enclosed environment (internal class)

Types of Sectionalizers:

– Blade-type: Such as ground sectionalizers, sliding, rotary, like line sectionalizer and knife-type models.

Types of Rotary Sectionalizers:

– Single-pole: One fixed and one movable pole.

– Double-pole: Two movable poles.

– Triple-pole: Around the center axis like a T-shaped structure.

What is a Breaker?

If we translate “دژنکتور” from French to English, we arrive at the word “Circuit breaker.” Therefore, in medium and high-voltage electrical systems, breakers are used for disconnect switches that can be operated under load. In general terms, disconnect switches that can be operated under load are called sectionalizers, and devices like miniature switches or automatic switches are referred to as breakers, commonly used in industrial electrical panels.

What is a Disconnect Switch?

A disconnect switch is a load-break power switch. In the presence of a connected consumer and current flow through the disconnect switch, the circuit can be interrupted while the consumer is still powered, based on a specific mechanism designed for it.

If we examine the literal meaning of “دژنکتور” (Disjoncteur) in French, we find that this word is written as “Disjoncteur,” different from the general perception that considers it an English word. We have explained in a comprehensive article what a disconnect switch is and its applications. It is highly recommended to read this article.

In addition to the manual circuit-breaking capability, a disconnect switch protects the circuit in case of a short circuit, similar to the function of a miniature circuit breaker (MCB).

Introduction to Types of Disconnect Switches

Now that we are familiar with the concept of a disconnect switch and its differences from a sectionalizer, let’s introduce various types of disconnect switches. First and foremost, we delve into the functionalities of disconnect switches.

Disconnect Switch Functionality:

To achieve the disconnect and reconnect function, separate springs are employed in disconnect switches. These springs are connected to each actuator shaft. The disconnect switch often has a manual or motorized charging mechanism for these springs, and the disconnection of the springs is accomplished by the energy released from the connected springs.

The release of these springs is facilitated by triggering a latch through the disconnect and reconnect coils. Each disconnect switch has separate coils called the connect coil and disconnect coil for its disconnect and reconnect mechanism.

These coils are controlled both manually and remotely (via relays and control rooms). Protection operations in panels are carried out through commands sent to the switch by relays. These commands ultimately energize the disconnect or connect coils, bringing the disconnect switch into operation.

Oil Circuit Breaker (OCB):

In this type of circuit breaker, the disconnect and reconnect mechanism is housed within a steel enclosure filled with oil, and the operation is performed using a strong spring. Due to the risk of the oil-filled enclosure exploding, this model of circuit breaker is less commonly used and has been replaced by other models.

SF6 Gas-insulated Circuit Breaker:

This type of circuit breaker is entirely filled with SF6 gas and, compared to other models, has smaller dimensions and produces less noise. Therefore, in locations where space constraints are an issue, and the importance of the noise level during disconnect and reconnect operations is crucial, this model is well-suited.

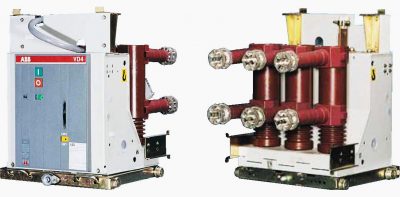

Vacuum Circuit Breaker:

In this type of circuit breaker, during disconnect and reconnect operations, no gas or oil is used; instead, a vacuum mechanism (an air-free chamber) is employed. These switches have minimal noise and are often used in public places such as metro stations.

In this article, we aimed to provide a definition of the sectionalizer and explain its differences from a circuit breaker. We sincerely appreciate your presence with us. Be sure to benefit from the guidance of electroshield experts when purchasing industrial electrical equipment to make the best choices and save on your expenses.