Understanding the different types of cables and gaining a deep knowledge of them can greatly assist you in selecting industrial cables and meeting your other needs. Be sure to stay with us as ElectroShield provides you with further explanations.

About Cables

Cables are recognized as one of the most versatile tools in today’s world. These tools are encountered in various environments such as homes, workplaces, vehicles, streets, universities, and even outside the city, playing a crucial role in the transmission of electrical currents and telecommunications.

To define a cable, it can be considered as a collection of one or more wire strands placed within a common insulating sheath. These cables are divided into various types based on human needs, ranging from transmitting electrical currents to sending signals and establishing a wide range of telecommunication functions.

Structure of Cable Types

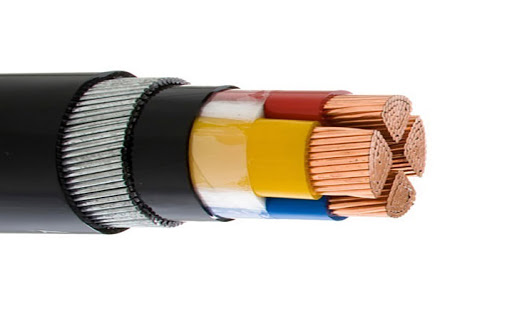

Different types of cables have different components, with some components being common and others varying in different types. Common components include the conductor and the sheath. Additionally, some cables have other additional components such as armor (mechanical protection) and electrical protection.

Conductor

The conductor, also known as the conductor, is responsible for the transmission of electrical currents. Copper, aluminum, gold, and silver are used as conductors. Copper has the most widespread use and is employed as the main conductor in most cables. Aluminum is used in cases where weight reduction is important.

Aluminum, with its lower weight, is used in places where weight reduction is crucial. However, it should be noted that aluminum has high electrical resistance and oxidizes over time when exposed to air. Due to the high cost of gold and silver, these two metals are usually not used in cable manufacturing and are only used in some parts of electronic devices.

Insulation

Insulations, as one of the fundamental components of cables, are formed from various polymeric materials. These insulations are divided into two categories: thermoplastic and thermoset, each having its own specific characteristics and applications. Thermoplastic insulations are heat-sensitive, and with an increase in temperature, they may deform or even melt. PVC, PE, and LSZH are examples of thermoplastic insulations used for general purposes, with PVC being recognized as the most widely used insulation type in the construction of various cables.

Thermoset insulations are resistant to heat and do not deform. XLPE, EVA, EPR, HEPR, and silicone rubber are examples of thermoset insulations. Cables with silicone insulation or mica tape along with XPLE are resistant to fire.

Electrical Protection

Some cables have electrical protection to combat electromagnetic fields and waves. Electrical protection includes copper or aluminum foil shields, copper shields, and braided shields (aluminum) that prevent the generation of noise.

Armor

Armor, or mechanical protection, is used in some types of cables to withstand impacts, heavy objects, cuts, and rodent damage. Cables with armor are known as armored cables, while those without armor are referred to as non-armored cables.

Armors are made of metal and come in various types. SWA armor includes a layer of galvanized steel with different diameters, providing over 90% protection. GSWB armor is made of woven galvanized steel wire, providing over 80% protection. GSTA armor consists of galvanized steel tape, offering nearly 100% protection.

Types of Cables and Their Classifications

Due to the extensive applications of various cables in everyday life, they are categorized into multiple classifications. These classifications are made based on various criteria to simplify the selection and purchase of cables, ensuring no mistakes occur in this matter. Here, the most important cable classifications are highlighted:

1. Classification Based on Working Voltage:

Cables are divided into four categories based on working voltage:

– Low Voltage Cable (LV): Used for electricity transmission with low voltage up to approximately 1000 volts, for example, in residential power cable installations.

– Medium Voltage Cable (MV): With a working voltage between 1 to 33 kilovolts, used for power transmission over short distances such as power distribution substations within cities.

– High Voltage Cable (HV): With a working voltage of 33 to 230 kilovolts, used for high-volume power transmission over long distances.

– Extra High Voltage Cable (EHV): Used when the working voltage is higher than 230 kilovolts.

These classifications will help you quickly and accurately identify your desired cable, ensuring informed and correct purchases.

Classification of Cable Types Based on Conductor Shape

The flexibility of cables, a crucial consideration in their selection, depends on their conductor shape. This leads to the classification of cables into three different groups, and we have detailed these classifications:

1. Twisted Type:

In this category, the cable conductor is twisted and has a circular or triangular cross-sectional area. These cables are known as Class 1 cables and, although they have limited flexibility, they exhibit higher electrical conductivity.

2. Semi-Shielded Type:

The conductor of semi-shielded cables is composed of multiple simple strands, introducing this cable as Class 2. This type of cable offers greater flexibility compared to Class 1 cables.

3. Shielded Type (Stranded):

With the highest flexibility, shielded cables are divided into Class 5 and Class 6. These cables are ideal for applications requiring extensive bending and movement.

Classification of Cable Types Based on the Number of Cores

Each cable has one or more inner cores, and the number of cores is determined based on the cable’s function.

Low Voltage Cables:

These cables have 1 to 5 cores and can be used for various needs, including single-phase or three-phase electrical power.

Medium Voltage and High Voltage Cables:

This category of cables has 1 to 3 cores and is used for the transmission of larger loads over longer distances.

Classification of Cable Types Based on Function

The extensive use of cables in the transmission of information and power has led to the division of these tools into three main categories based on their functions:

1. Electrical Power Transmission:

LV, MV, HV, and EHV cables fall into this category. This includes various types of cables used for the transmission of power and electricity at different voltage levels. From LV cables for regular use to EHV cables for high-voltage transmission, each has its specific applications.

2. Signal Transmission:

Telecommunication, network, and coaxial cables are used for the transmission of various signals. Coaxial cables, representing this category, are used for transmitting audio and video data using a stranded copper or aluminum wire and polymer insulation. These cables are also equipped with copper screening for electrical protection.

3. Antenna Cable:

An antenna cable is a type of coaxial cable with a 75-ohm impedance used for transmitting audio and video signals from the antenna to the television. This cable has been a reliable solution for signal transmission since 1936 and comes in various impedance types.

In the following sections, we will delve into explanations of various telecommunication cables and network cables.

Fiber Optic Transmission: Optical Cables in Telecommunications

Optical cables, known as fiber optic cables, are composed of optical fibers that are similar to stranded wire-like strands, made of glass or plastic. These optical fibers receive light at one end and emit it at the other end after covering long distances.

The primary application of optical cables is in the field of telecommunications. This type of cable has a significantly high bandwidth, covering data transfer speeds up to 10 gigabits per second. Additionally, the transmission speed in optical fibers is much higher compared to electromagnetic waves.

In the classification of optical cables, two common types exist:

1. Outdoor Fiber Optic Cable:

This type of cable has a black PE (polyethylene) coating and is used for communications outside of buildings and in various environmental conditions.

2. Indoor Fiber Optic Cable:

Cables in this category have a yellow or orange PVC (polyvinyl chloride) coating and are used within building spaces.

Telephone Cable: Telecommunications Communication

Various types of telecommunication cables are used for the transmission of analog and digital signals in telecommunications networks. These cables are divided into two categories: copper telecommunication cable and optical telecommunication cable. Each of these categories is used based on diverse telecommunication needs.

Copper Telecommunication Cable: Efficient Transmission of Signals without Noise

Copper telecommunication cables, with a stranded copper conductor, come in thicknesses of 0.4 mm (0.4), 0.5 mm (0.5), and 0.6 mm (0.6). The diameter of the conductor’s cross-sectional area not only determines the flexibility of the cable but also directly enhances the power transmission capability of the signals. A larger cross-sectional area of the strands provides better capability to transmit signals without noise. Therefore, using the highest cross-sectional area is recommended for long distances to prevent signal degradation.

Telephone Cables with Diversity in Pair Counts: Boundless Communication

Telephone cables, considering the diversity in pair counts, utilize two main and several sub-color groups. The primary colors, including white, black, red, yellow, and purple, along with secondary colors such as blue, green, orange, brown, and gray, create various pairs. Each pair is formed by combining one primary color with one secondary color. These combinations, based on different telecommunication needs, make up 25 pairs of strands.

Telephone cables are classified into various types based on the number of pairs:

1 pair, 2 pairs, 4 pairs, 6 pairs, 10 pairs, 15 pairs, 20 pairs, 25 pairs, 32 pairs, 50 pairs, 100 pairs, and 200 pairs.

In cases where the number of pairs exceeds 25, each set of 25 pairs is twisted together, creating subsequent sets of 25 pairs. This method enhances flexibility and signal transmission quality.

Advanced Technology in Telephone and Network Cables: A Comprehensive Overview

Types of telephone cables with ground and aerial contrasts: Applications and characteristics

Telephone cables with ground and aerial contrasts have two main categories. Aerial telephone cables, with a black sheath, are resistant to rain and sunlight. This type of cable is drier and can withstand various weather conditions. Ground telephone cables, with a gray color, have more flexibility and are usually used for cabling underground or inside buildings (in pipes).

Network Cable: Creating High-Speed Connections

Network cables are used to establish connections between various devices and transmit data. Each network cable consists of 8 wire strands paired together in a twisted form, forming 4 pairs. These strands are enclosed in a PVC sheath.

There is a wide variety of network cables; some of them have copper shields and aluminum foil to prevent noise. Types such as UTP, FTP, STP, SFTP, and SSTP, with differences in shielding and foil, meet different needs. These cables are classified into 8 categories from CAT1 to CAT8 in terms of construction technology, and with advancements from generation to generation, bandwidth and data transfer speed increase.

Ground Cable Technology: Flexibility and Diverse Applications

Ground cable, also known as dry cable, is a type of cable used for wiring underground or in indoor environments of buildings. This cable, with limited flexibility and of the stranded type, is suitable for dry and humid environments and even outdoor spaces.

Classification of Ground Cables: Telecommunication and Electrical

Ground cables are divided into two categories: telecommunication and electrical. Electrical cables are used for the transmission of electricity in various locations. These cables are produced and supplied with different conductor types, number of strands, and nominal voltage.

Cable Connections: From Connectors to Joints

During the cable installation process, various connections may be required. Connectors are used to establish strong connections between cables, creating a secure link. Connectors are responsible for connecting two or more cables and are usually made of different materials such as iron, steel, and PVC.

Cable Shoes: Tools for Connecting Cables to Circuits

To connect a cable to a circuit or various types of switches, a tool called a cable shoe or cable lug is used. These tools are usually made of copper and come in various shapes.

Metal-Free Connectors and Cable Shoes: Multipurpose Connections

When the conductor material on both ends of the connection is different, metal-free connectors and cable shoes are used. These tools ensure a secure connection between cables and prevent any noise or interference.

Comprehensive Guide for Choosing the Best Cable

When selecting a cable for building wiring, attention to fundamental principles is essential. As cable types vary, paying attention to key factors can assist in choosing the best and most suitable cable. This guide introduces these factors:

1. Type of Function:

Depending on your occupational needs, choosing the appropriate cable is crucial. Use coaxial or network cables for signal transmission. For electricity transmission, you need low, medium, or high-pressure cables. Exposed to physical hazards? Use armored cables. For lighter weight, cables with aluminum conductors are suitable.

2. Calculating Consumed Current:

The electric current passing through a cable generates heat. Accurately calculating the consumed current is essential. The cable’s allowable current should always be higher than the consumed current to prevent cable burning.

3. Environmental Conditions:

Factors such as cable structural characteristics, environmental weather conditions, and the cable’s installation location have an impact. These factors affect the cable’s heat exchange rate and should be considered when selecting the desired cable.

Considering these factors not only enhances the quality of connections but is also crucial for safety.

Comprehensive Guide for Calculating Consumed Current and Voltage Management

In the complex world of electrical energy, precise calculations and proper voltage management are critical. Various formulas are used to calculate the consumed current in single-phase and three-phase networks with direct and alternating currents.

Calculating Current in Single-Phase Network with Direct Current:

\[ I (\text{Amperes}) = \frac{\text{Voltage (Volts)}}{\text{Consumed Power (Watts)}} \]

Calculating Current in Three-Phase Network with Alternating Current:

\[ I (\text{Amperes}) = \frac{\text{Consumed Power (Watts)}}{\text{Voltage (Volts) \times Power Factor}} \]

To accurately calculate the consumed current, the power factor is also considered.

Practical Example:

To calculate the consumed current of a device with a power of 2800 watts, voltage of 380 volts, and a power factor of 0.9 in a three-phase network, the mentioned formula is used.

Guide to Cable Buying: How to Identify Quality Cables?

Weather conditions are one of the influential factors on the performance and lifespan of cables. To ensure quality and choose the best cable, special attention should be paid to the weather characteristics of the destination region.

Key Features of a High-Quality Cable:

After determining the type and specifications of the required cable, recognizing the features of a quality cable is of paramount importance. Some of these features include:

– Quality Copper:

– The copper surface should be bright and shiny, as oxidation indicates undesirable cable quality.

– Copper strands should be flexible and not break when bent.

– Uniform Diameter:

– The diameter of the conductor cross-section should match the declared value in the cable catalog.

– Arrangement of Strands:

– Strands should be precisely positioned in the center of the insulation and separated from each other.

– Conductor Placement:

– Each conductor should be placed in the center of its insulation, and the thickness of the surrounding insulation should be uniform.

– Outer Surface of the Sheath:

– The outer surface of the cable should be uniform and smooth, without depressions or protrusions.

Final Points:

Additionally, purchase the required cables from reputable brands and stores. Following these guidelines, you can protect yourself from buying various high-quality cables and counterfeit products.

The above article has been compiled to familiarize you with the types of cables and how to practically choose them. We accompany you on this journey and are always available to answer your questions.